04 CNCing an Harley Davidson part from sctatch

In this 2 parts episode Custom Cez will design and machine a part for his bike from aluminum and copper from zero.

Part 1 - THE DESIGN

In this first part Custom Cez takes care of the design using a CAD software to recreate the form of the original part and then design the new one while taking care of original dimensions and tolerances.

What did we do:

- scan of the original part

- reproduction of original part in CAD

- creative design

- design consideration

- double sided machining technique

- design testing

Part 2 - MACHINING

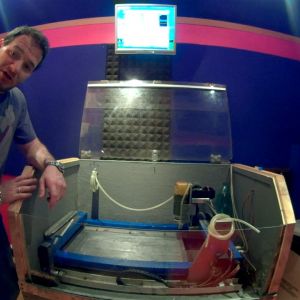

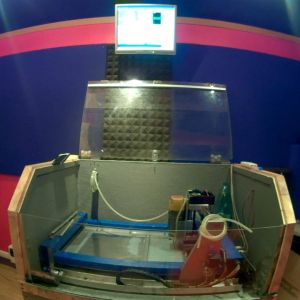

In this second part Custom Cez machines the pieces in his home made CNC machine. Hi talks about stock positioning, referencing the axes, different metal considerations while completing the process all the way to the installation on the bike. The principles described in t his episodes can be applied to pretty much anything, the only limit is our own creativity.

What did we do:

- stock positioning in the CNC machine

- zeroing of the x, y, z coordinates

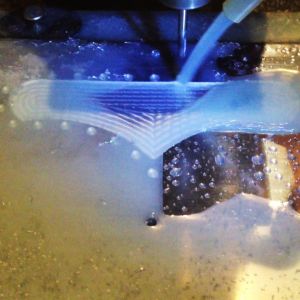

- back face machining

- flip and stock repositioning for 2nd face machining

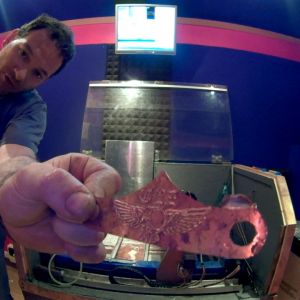

- part removal

- engraving on copper

- polishing

- installation